Circuit Design | Product Development | Prototyping | Fabrication

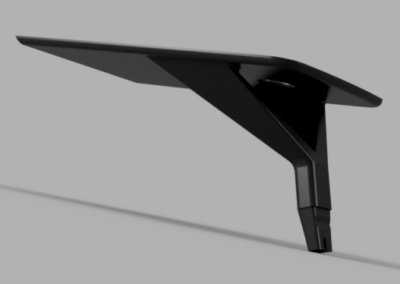

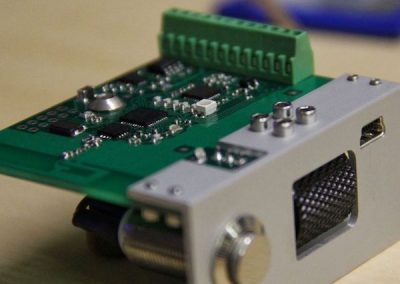

CloudGuage Prototype

Let’s forge amazing new ideas into products.

Your go-to team for designing and prototyping of new and improved products

From idea to product we are here for you every step of the way.

1.

Discovery and Prototype

From our first meeting we will sitdown with you to undestand the main goals for the product and user experiance. We do this with what we call the story-based product walkthrough. After our initial meeting we will combine the findings from the product story, our internal research and develop a plan of action, lead time and costs estimate to design and build a functioanl prototype.

2.

Product Development

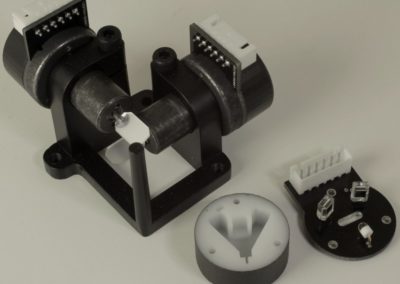

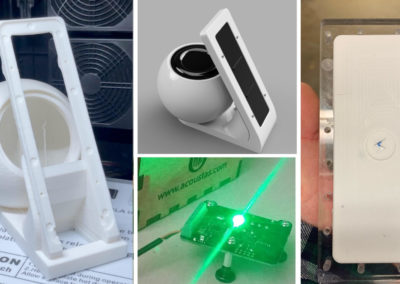

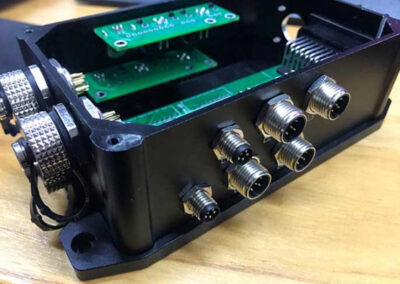

Product development phase is all about creating your prototype. Depending on the product needs it can be custom embedded systems, circuits, 3d prints, enclosure design, web portal or native app, we build it and testing it for functionality and usability. After we refine the functionality and user experience in the lab and in the real world, the prototype along with the design files are ready for manufacturing.

3.

Product Launch and Support

Next our team will help you with regulatory certifications such as Federal Communications FCC), Industry Canada (IC), UL1642, 7. UL2054, and 8. UN/DOT 38.3. After that the prototype goes to manufacturing and we help every step of the way. But we don’t stop there we support you on as-needed basis and help with anything needed from design updates to software improvements and over the air updates. Your success is our top priority.

Popular services at lava labs

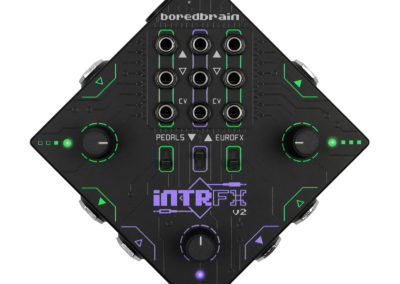

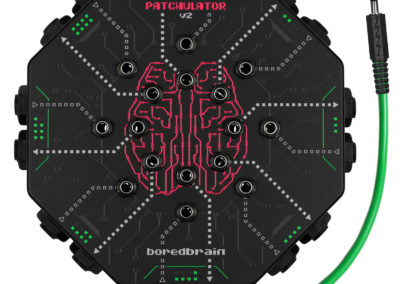

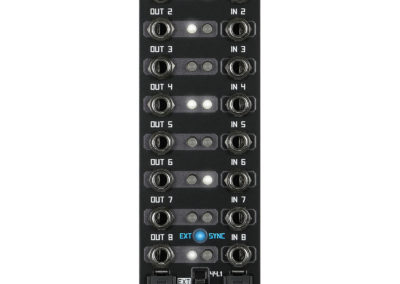

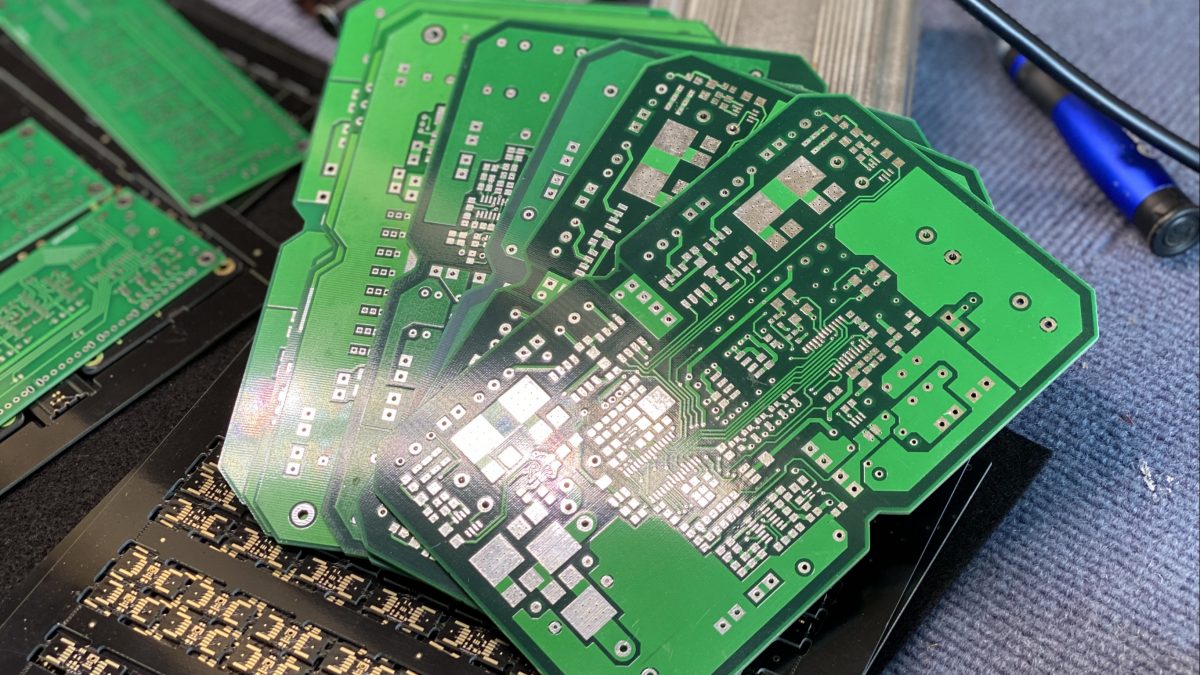

Electrical Engineering

- Circuit Design and Testing

- Electronics Prototypes

- Firmware and Drivers Development

- Components Selection and Testing

- Bill of Materials Research

- Schematic Design

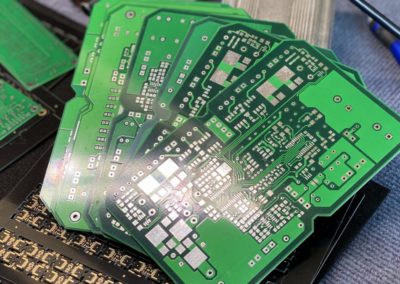

- Circuit Layout

- PCB manufacturing

- Circuit Assembly

- Testing and Quality Assurance

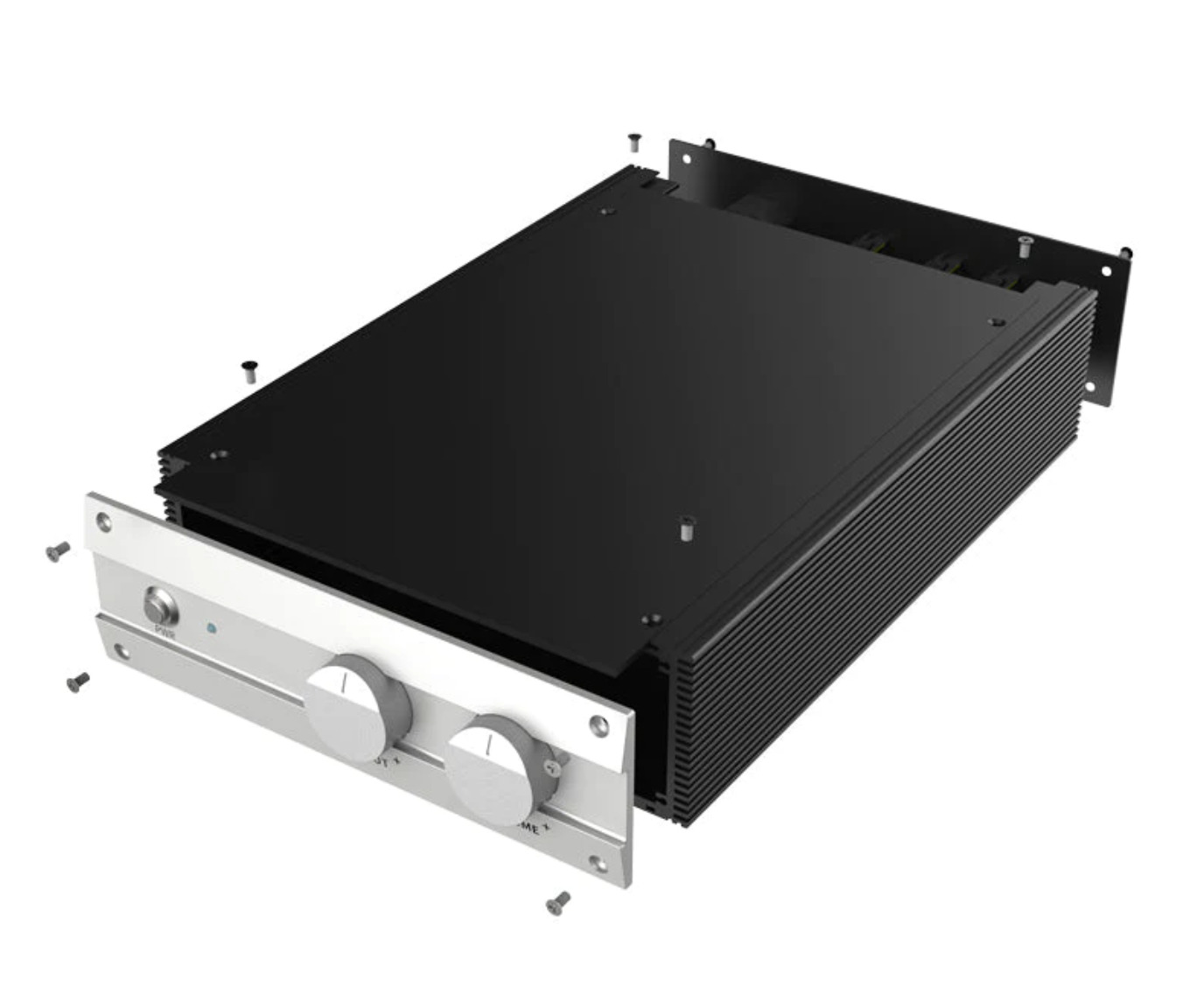

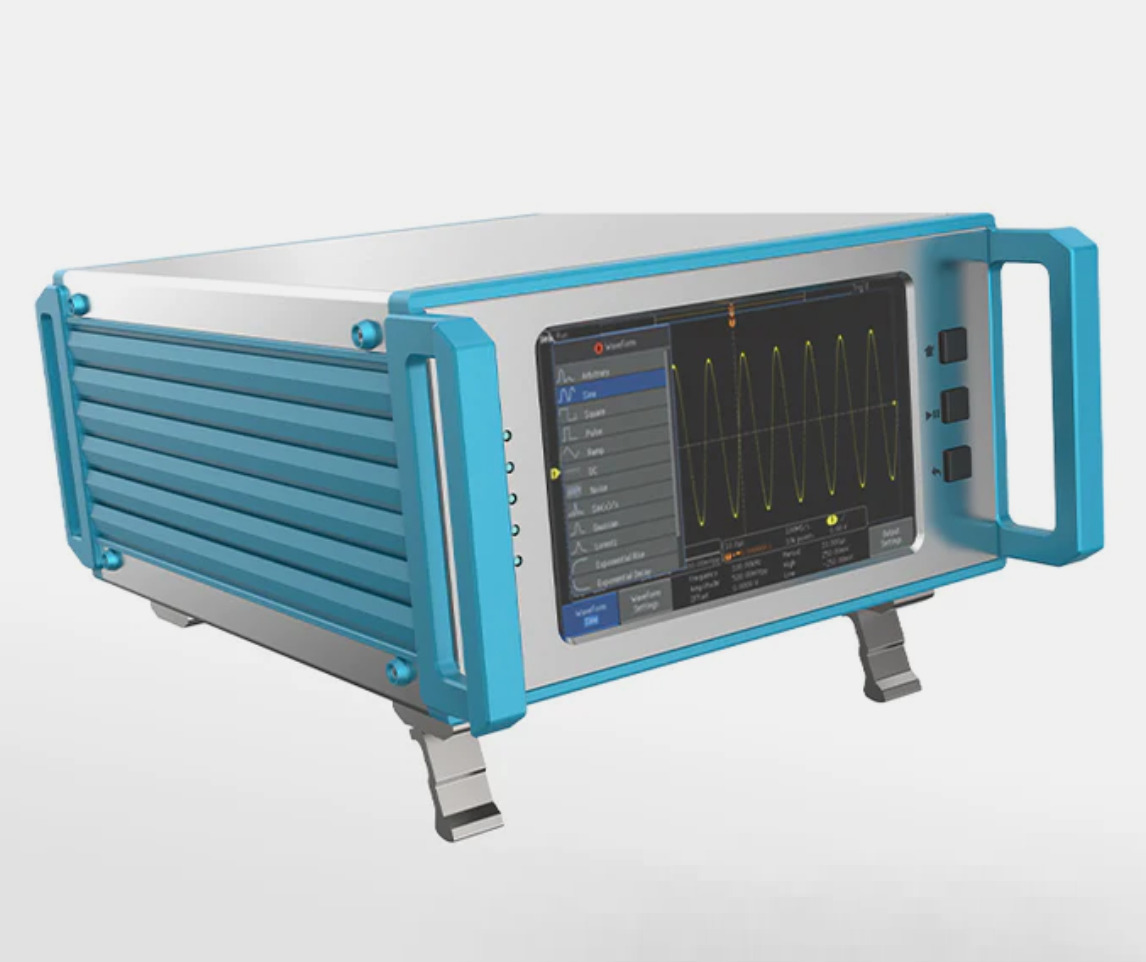

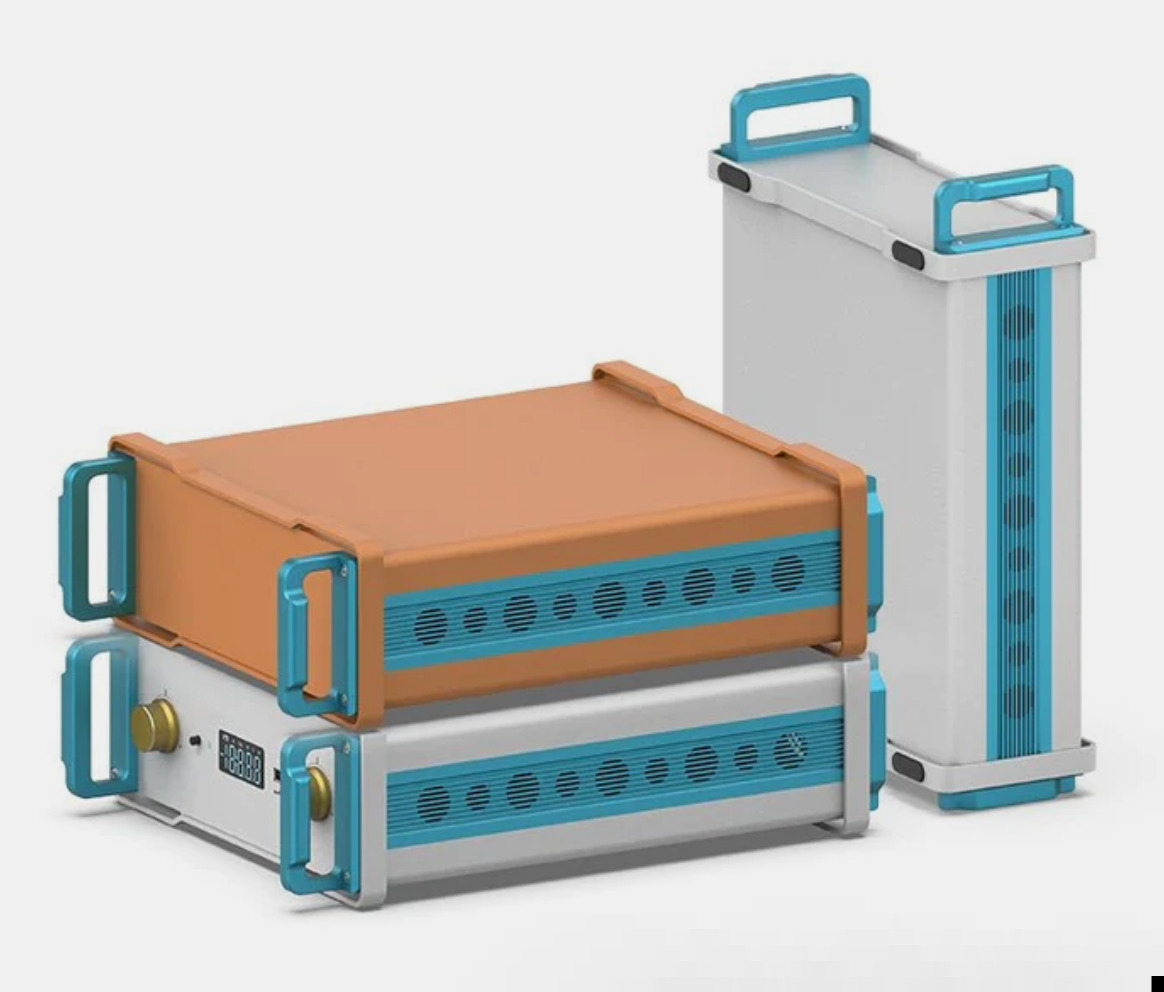

Electronic Enclosure Solutions

- Over 500 options for enclosures

- Plastic and aluminum IoT device enclosurs

- Amplifier Equipment Enclosure

- 19 Inch Server Chassis

- Sheet metal boxes

- Rack Mount Chassis

- IP68 Waterproof Boxs

- Small Junction Boxs

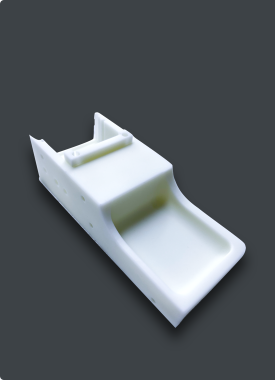

Additive Manufacturing

3D printing

- Stereolithography (SLA)

- Multi Jet Fusion (MJF)

- Selective Laser Melting (SLM)

- Fused Deposition Modeling (FDM)

- Selective Laser Sintering (SLS)

Specializing in

IoT Hardware Development

- Internet of Things scalable devices

- Smart battery powered devices

- WiFi and Bluetooth

- Cellular connectivity Verizon, AT&T, T-Mobile, Hologram

- Sensor integration

- Data acquisition

- Battery powered miniature devices

- Embedded Firmware

Industrial and Agricultural Environments Monitoring

- Chemical and Gas Monitoring

- Cellular connectivity

- Liquid Level and Flow Sensors

- Accelerometers and Gyroscope

- Temperature and Humidity

- Light | Vision | LiDAR | Time of Flight Sensors

- Ultrasonic Sound Sensors

- Magnetic and Hall Effect

Power Electronics Design

- Low and High-Voltage Systems

- Inverters/Converters

- Advanced Motor Controllers

- Renewables & EV Systems

- Capacity Simulation/Evaluation

- Charge Management

- Wireless Qi Charging

- Li-Poly | LFP | LTO | NiMH | NiCd

Audio Circuit Design

- Digital Signal Processing

- Microphone Arrays

- Analog and Digital Signals

- Bluetooth and WIFI Audio

- Audio Filtering

- Voice Control

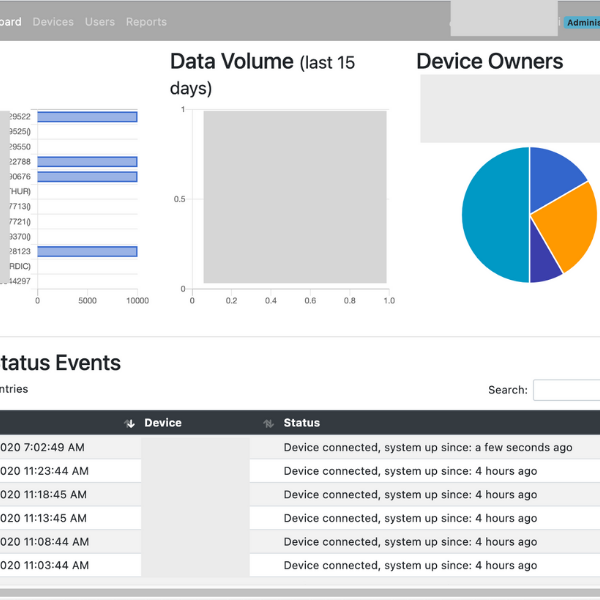

IoT Web App Portal Development

- Access all sensors/devices collated into a portal

- Amzon AWS | Lambda | IoT Core

- Web Apps for Realtime Data

- Hardware Control via Apps

- SaaS Software Development

- Firmware and Drivers

- Point of Contact for IoT

- Mobile iOS and Android

You’re in good company! Trusted by our clients for over 12 years and counting.

What our clients are saying…